Cochlea hexagonalis involucri angularis DIN7991, chalybe carbonico obducta, gradus 8.8, 10.9

Cochlea hexagonalis involucri angularis DIN7991, chalybe carbonico obducta, gradus 8.8, 10.9

Descriptio

CELERITERResponsum

CELERITERCitatio

CELERITERTraditio

PARATUS AD TRADITIONEM

Decem milia et plus SKU in horreo

Pro rebus RTS nos obligamus:

70% res traditae intra quinque dies

80% res traditae intra septem dies

90% res traditaeintra decem dies

Magnae copiae emptionum, quaeso ministerium clientium pete.

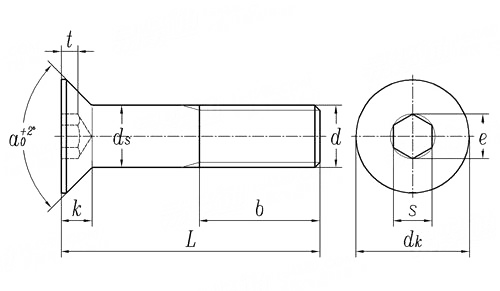

| d | M3 | M4 | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | (M22) | M24 | |

| P | Vox | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 |

| α | tol. (+2) | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | LX° | LX° |

| b | Longitudo ≤ 125 mm | 12 | 14 | 16 | 18 | 22 | 26 | 30 | 34 | 38 | 42 | 46 | 50 | 54 |

| 125<L ≤ 200 | / | / | / | 24 | 28 | 32 | 36 | 40 | 44 | 48 | 52 | 56 | 60 | |

| L>200 | / | / | / | / | / | 45 | 49 | 53 | 57 | 61 | 65 | 69 | 73 | |

| dk | Maximum = Nominale | 6 | 8 | 10 | 12 | 16 | 20 | 24 | 27 | 30 | 33 | 36 | 36 | 39 |

| Min. | 5.7 | 7.64 | 9.64 | 11.57 | 15.57 | 19.48 | 23.48 | XXVI.XLVIII | 29.48 | 32.38 | 35.38 | 35.38 | 38.38 | |

| ds | Maximum = Nominale | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

| Min. | 2.86 | 3.82 | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | |

| e | Min. | 2.3 | 2.87 | 3.44 | 4.58 | 5.72 | 6.86 | 9.15 | 11.43 | 11.43 | 13.72 | 13.72 | 16 | 16 |

| k | Maximus | 1.7 | 2.3 | 2.8 | 3.3 | 4.4 | 5.5 | 6.5 | 7 | 7.5 | 8 | 8.5 | 13.1 | 14 |

| s | Nominalis | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 10 | 12 | 12 | 14 | 14 |

| Min. | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 10.025 | 12.032 | 12.032 | 14.032 | 14.032 | |

| Maximus | 2.1 | 2.6 | 3.1 | 4.12 | 5.14 | 6.14 | 8.175 | 10.175 | 10.175 | 12.212 | 12.212 | 14.212 | 14.212 | |

| t | Maximum = Nominale | 1.2 | 1.8 | 2.3 | 2.5 | 3.5 | 4.4 | 4.6 | 4.8 | 5.3 | 5.5 | 5.9 | 8.8 | 10.3 |

| Min. | 0.95 | 1.55 | 2.05 | 2.25 | 3.2 | 4.1 | 4.3 | 4.5 | 5 | 5.2 | 5.6 | 8.44 | 9.87 | |

Descriptio accurata

Fibulae altae firmitatis, cum galvanizatae sunt, crispitudinem praebebunt. Speciali cura indigent.

Fragilitas hydrogenii plerumque fractura tarda sub tensione insignitur. Inventis fontibus, laminis, cochleis, laminis elasticis, aliisque partibus galvanizatis autocinetorum, paucis horis postquam fractura coniuncta est, proportio fracturae 40% ~ 50% erat. In processu usus partium cadmio obductarum producti specialis, fractura per seriem (batch fissure fracture) orta est, et problema nationale grave solutum est et processus dehydrogenationis strictus constitutus est. Praeterea, sunt quaedam fragilitas hydrogenii quae phaenomenon fracturae tardae non ostendit, ut: suspensiones electrogalvanizationis (filum chalybeum, filum cupreum) propter multiplices electrogalvanizationis et decaptationis penetrationem hydrogenii graviorem faciunt, saepe in usu plicae apparent, quae phaenomenon fracturae fragilis fiunt; mandrel sclopeti, post pluries chromationis, ad terram cecidit et fractum est; quaedam partes extinctae (magna tensione interna) decaptando findunt. Hae partes graviter hydrogenatae sunt et sine tensione externa findunt, quae amplius ad pristinam duritiam per dehydrogenationem restituendam adhiberi non possunt.

Quo maior est robur materiae, eo maior est sensibilitas ad fragilitatem hydrogenii. Haec est notio fundamentalis quae a technicis curationis superficierum explicanda est cum specificationes processus galvanoplastiae conficiuntur. Chalybes quorum robur tensile σb > 105 kg/mm2 a normis internationalibus requisitum, tensioni ante galvanoplastiam et curationi dehydrogenationis post galvanoplastiam proinde subiici debent. Industria aeronautica Gallica curationem dehydrogenationis correspondentem requirit pro partibus chalybeis quorum robur flexionis σs > 90 kg/mm2 est.

Propter bonam correspondentiam inter firmitatem chalybis et duritiem, intuitivum et commodius est iudicare sensibilitatem materiae ad fragilitatem hydrogenii ex duritie quam ex firmitate. Quia perfecta delineatio producti et processus machinationis duritia chalybis notari debet. In galvanoplastia, invenimus duritiem chalybis circa HRC38 periculum fracturae fragilitatis hydrogenii ostendere coepisse. Pro partibus maioribus quam HRC43, dehydrogenatio post galvanoplastiam consideranda est. Cum duritia circa HRC60 est, curatio dehydrogenationis statim post curationem superficialem peragenda est, alioquin partes chalybis intra paucas horas findescent.

Sarcinatio

De nobis

* Diagramma sequens varias "incoterms" commerciales identificat. Quaeso, eam quam mavis elige.

PRODUCTUM VENDITIONIS CALIDISSIMUM

Qualitas Prima, Salus Garantita